Anyone who has ever tried a massive machine like a bulldozer or crane knows how vital is the maintenance. When all aspects of a machine functions together properly, it aids in the effectiveness of a machine performing its designated function. Using Genuine Parts- The Functions of any machine depend on the different parts used in it. The flanged sleeve bearing is one of the key parts contributing to this. This CIXIHOTO unique section supports ballast, thus making it cheaper in the long run to maintain the machines.

Flanged sleeve bearings, designed for longevity, can be utilized as money-saving options. They can bear a tremendous amount of weight without them breaking or getting damaged. That means you will not need to replace them as often as some components that wear out quickly. The bearing sleeve best part is that as you do not need to change them, you spend less on repairs & save more for other essentials!

Flanged sleeve bearings are excellent for large machines, and they come with a lot of advantages. To start, they harbor heavy loads with ease – something that you always require for a machine working overtime on big jobs. Second, they are durable enough to stand the test of time in harsh conditions. So you can rest assured that you will not have to canvas for replacements anytime soon. Lastly, they reduce friction and allow parts to move freely. In other words, they maintain the machinery for prolonged periods of effective and seamless operation.

Flanged sleeve bearings are quite a good option if you think of weights because this is one major reason to use them. Most large machines exert considerable stress/strain on its components, making it essential that they are rugged enough to withstand wear. However, flanged sleeve bearings are designed to support the extra load, making them a great option for heavy-duty equipment. Which CIXIHOTO is to say your machines will run with no breakages.

Because flanged sleeve bearings are extremely strong, they are constructed to endure. Even Heavy machinery can cause tremendous cost on parts which eventually needs to be repaired. Yet flanged sleeve bearing designs are intended to withstand demanding use while offering long life integral to not need replacement. This CIXIHOTO bearing sleeve types saves money and time for businesses that utilize heavy duty machinery.

Flanged sleeve bearings-As also a call for a flanged-bearing, Flanged sleeve bearings are still widely used in factories; since it is used to reduce the friction between moving parts. Like big machines that rely on many pieces to make sure something gets done the right way. Refraining the friction among these parts is accomplished with flanged sleeve bearings to help ease this process. With less friction, these parts can move more fluidly and thus keep the rest of the machine functioning well.

Flanged sleeve bearings used in large machines not only ensure better functionality but also minimizes the costs associated with repair and maintenance. Hence, due to their ability to carry heavy loads that minimize friction and wear they make heavy machinery run for longer periods of time without any dysfunction. And by depreciation, I mean that means less downtime (machines not running) and fewer expensive repairs. All of this adapter bearing sleeve can really save a lot of bucks for your company in the long run, so, you can divert your attention to more pressing matters.

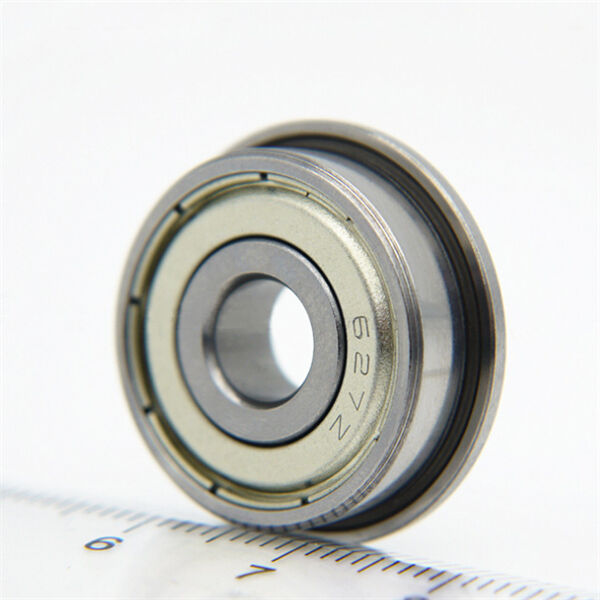

CIXI HOTO offers thousands of Flanged sleeve bearing sleeves in SS Alloy, Carbon steel and bearing steel grades.

CIXI HOTO Flanged sleeve bearing 40 production lines, which allowed for the production of a rapid lead time.

Flanged sleeve bearing produce kinds of ball bearing, bearing component (cage and sleeves, balls, seal) as well as bearing steel pipe and we also provide single-stop service for ball bearings and solutions.

CIXI HOTO has strong quality control system, Flanged sleeve bearing certifications AHSAS18001, ISO14001, and ISO14001: 2016.