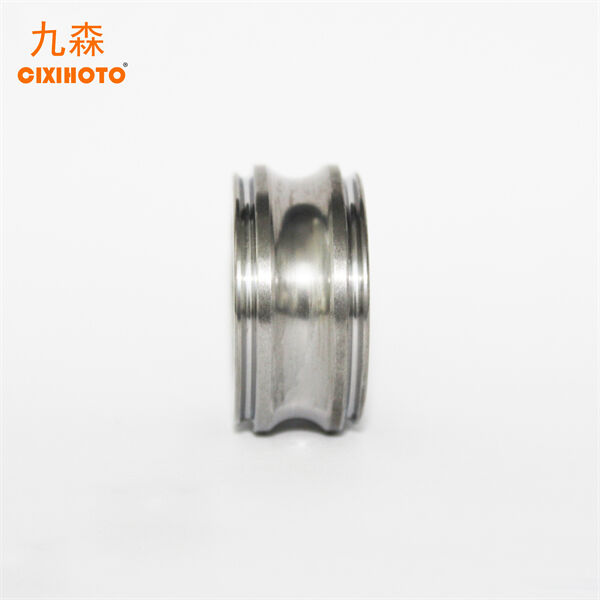

You may ask, what are bearing sleeves, anyway? Okay, these are circular in a shape and they surround along with a shaft — which is a rod that is long and helps in the connection of the machine components. Basically, sleeve bearings reduce friction, which is when two parts rub together. With the friction reduced, machines perform better and last longer.

Think about riding a bicycle. Without assistance, the pedals and wheels would rub against one another making it virtually impossible to pedal, and the bike would quickly wear out. However, when plain bearings are employed, the bikes' cranks and wheels can turn freely. The reason for this is that sleeve bearings enable free movement where the sleeve bearing inserts its sleeve, therefore the bike's ride becomes much smoother as it takes out a lot of load. Similarly, sleeve bearings allow the machines to function better by reducing friction between them and provide smooth motion between all.

There are many advantages of utilizing bearing sleeve typess within machines. They may, for one, save energy and reduce costs. As sleeve bearings minimize frictional contact and drag, they reduce the work the machine must do to perform its job. That means it can conserve power, which can also translate to cost savings.

Also, they can improve how machines operate. These help in noise and vibration dampening when they operate which is crucial for certain types of machines that need to be operated perfectly such as in factories. A person will also make it a week when machines are quieter and relatively smoother, which adds advantages for anyone around them to work better.

Lubrication of sleeve bearings is critical to keep them properly functioning. With proper lubrication, friction, wear are reduced, and bearings will be safe and last longer. When you add a lubricant, you are adding an agent that allows for smooth motion between parts without grinding against each other.

Various forms, including oils and greases, are available for lubricants. There are many options available, and the correct lubricant type depends on the needs of the sleeve bearing and the environment where it will be used. Always use the manufacturer-recommended amount— using too little or too much lubricant can cause problems that will quickly wear out the bearings.

Another key point is to routinely inspect the bearings for failure. Check for things like cracks or chips, or anything else that might cause them to not perform well. Replace any you see as quickly as possible to avoid more damage to the machine. Monitoring these can make your machine work smoothly and save you from bigger problems later.