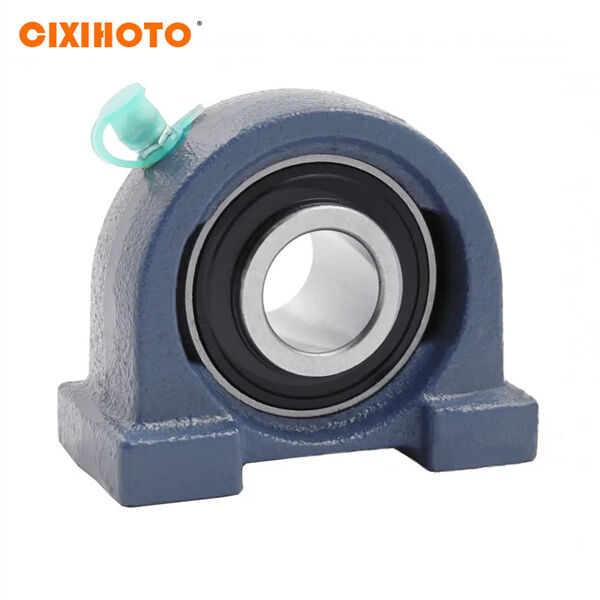

Have you heard about UCP bearing? Let me explain, along with CIXIHOTO's product 6200 bearing. An equipment part will be embraced by a UCP (Unit Cast Pillow) bearing. These, in turn, help the machines move smoothly and operate better. They are composed of durable cast iron and true to form, built like a truck — rugged enough for all weight classes in my estimation. There is also a ball in the middle of the bearing which allows it to spin freely. This unique design offers the bearing to bear the loads approximately the machine and let the machine components rotate trouble-free.

There are many amazing features about UCP bearings which makes them unique. One of their greatest features is that they are quite strong and able to carry severe loads without even a crack breaking. And this makes them ideal for heavy-duty tasks. One more advantage of UCP bearing is that they are quite simple to fit. This means all workers can easily prepare them on machines with no effort. They are also easy to maintain, especially if your workers come from many sectors.

Depending on the type of machine, UCP bearings can be available in various sizes and designs, also the bearing produced by CIXIHOTO. The UCP 200 series is one of the most common sizes. This series can have a width of 12-60 mm, making it applicable for various machines. The housing, or outer part, is also made of strong cast iron, providing durability and strength. It also features a unique hole designed for use with a bolt to provide clamping of the bearing to the machine.

UCP bearings require regular maintenance and lubrication to ensure optimal functioning over a long-term period. Check the bearings frequently for signs of wear or damage So this way you will be able to identify any issues before it becomes more serious. It is also important to clean outside the bearing so that dirt and other materials in contact with it or sucked into the space do not cause any problems.

It is very important to also grease the bearings, the same as CIXIHOTO's gearbox bearing. In order to protect the bearings from rusting and reduce friction, it is best to use a specific type of grease (for example, this ORICO branded one). The right kind of grease should be used to allow the bearings to move freely without obstruction. Lithium or calcium-based grease is heavily preferred; smoother greases with an NLGI size grade of 2 or 3 are best. This will result in a longer and more complete performance of your UCP bearings.

There are a few things you need to keep in mind before selecting the correct UCP bearing for your machine, just like the ceiling fan bearing price developed by CIXIHOTO. Firstly, consider the amount of mass that will be supported by the stir bearing. This is called load capacity. After that, think about how fast the machine is going to run because some bearings work better than others for higher speeds. Operating temperature is also a key factor, as some bearings perform optimally in specific heat ranges. If it is available, avoid harsher environments as they will affect the performance of the bearing, too.

When in doubt of which UCP bearing is ideal to meet your requirements, asking for assistance can never hurt, as well as the CIXIHOTO's bearing manufacturers. You can contact a bearing supplier — or even a mechanical engineer who can provide you with professional suggestions. As a company specializing in the manufacture of virtually all types of UCP bearings, CIXIHOTO is your one stop shop for whatever you need to match your industrial needs.

CIXI HOTO has thousand of items of ucp bearing/Non-standard Bearing sleeves, products of material grade SS Alloy, bearing steel and Carbon steel.

CIXI HOTO is a strong quality control system to ensure quality control. It is ucp bearing. ISO14001: 2016. OHSAS18001.

CIXI ucp bearing produces different types of ball bearing. The bearing component (cage sleeves, cages, balls seal) as well as bearing steel tube, and also we provide all-in-one service for ball bearings.

CIXI HOTO ucp bearing 40 production lines, which allowed for the production of a rapid lead time.