There is also a uniquely designed metal sphere which among mechanics is known as the "bearing sleeve" which facilitate smart machine functioning and also ensure longevity. These metallic spheres could be commonly observed in various fields such as in factories, automobiles as well as aeroplanes. But they may seem tiny and insignificant, but perform a very BIG job. They give moving parts of various machines a smooth, frictionless surface, a crucial factor determining the machine performance situation.

In factories and other areas where machines are used, sealed bearings can be extremely beneficial. The reason that they are so handy is mainly because they were hidden from dirt, dust, and other small particles. Such things can infiltrate machines, making them lag and wear out faster. Sealed bearings on machines improve life expectancy of each machine and performance versus machines without sealed bearings. Sealed bearings are also unlikely to undergo rust formation. When metal gets wet, and exposed to the elements, it will rust, and this leads to failure of rolling components, but sealed bearings are built not to ever have this issue.

It reduces friction and heat, enabling machines to operate more efficiently. Friction is what occurs when two surfaces rub together, like when you rub your hand on a coarse surface. Such rubbing can lead to wear and tear so the machine may get damaged as well. These types are black in color and have some sort of coating, which helps them move with minimal friction (the less the friction, the better). This causes less friction and generates less heat. This is great because excess heat can lead to parts of the machine burning out. Sealed bearings make machines stay in service for longer and perform better, thereby reducing time and energy.

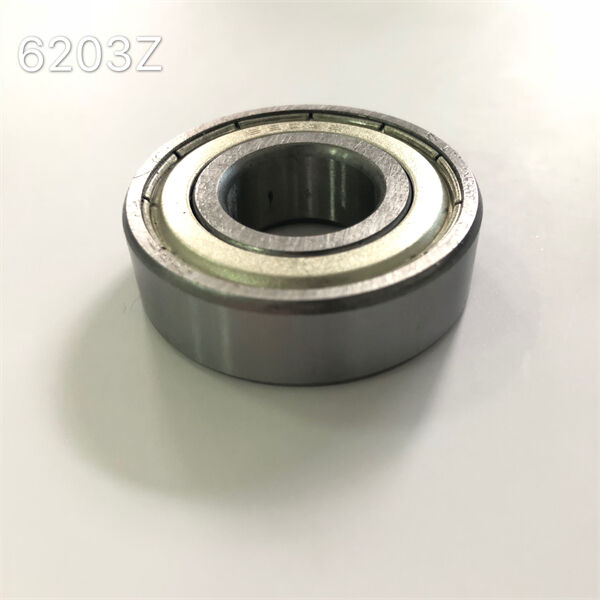

There are a million different sealed types, but the thing they all have in common is they're protecting the metal balls inside. The most common types include rubber seals, which do a great job of keeping dirt and dust out. Rubber seals are soft and pliable so very few things can get inside. There is likewise metal guards, which are better and can secure metal spheres as hitting or breakage. Also, hybrid bearings that use a blend of metal and ceramic materials These hybrid bearings are also a smart choice for machines as they further reduce friction and wear.

If you want all your machines to run properly for years, you need to use high-quality bearing sleeve types. Low-cost bearings may appear identical to higher quality ones, but they might be of inferior quality. As a result, they can become worn out more quickly than you would like. Your machines might end up breaking down and needing costly repair if your bearings are also wearing out at a fast pace. Which is why it's worth spending a little more on quality bearings. CI CI HOTO is a high-end sealed bearings company. Their bearings are built for longevity and performance in a wide range of climates, so that your machines are always safeguarded and running efficiently.

To create products in an efficient manner, manufacturing plants depend on machines and therefore any downtime caused by a broken or malfunctioning machine is costly. Production is disrupted if machines break down, which is hardly good for business. They are designed to last longer and operate more efficiently than other bearing types, which can, in turn, cut down on downtime and maintenance costs with the adoption of sealed bearings. This implies that if machines have sealed bearings, they can operate for longer hours without repair or replacement. Also, sealed bearings require little to no maintenance since dirt and dust can not penetrate them. This implies that they don not have to be cleaned or oiled as often, therefore freeing up time and efforts.