Support bearings rubber are critical components for machines that move and shake! Have you ever seen a big machine like a construction vehicle, or factory equipment, and noticed how it does this shaking thing at times? The vibrations can affect the working capacity of the machine and hinder its proper functioning. That is why, enter bearing sleeves!

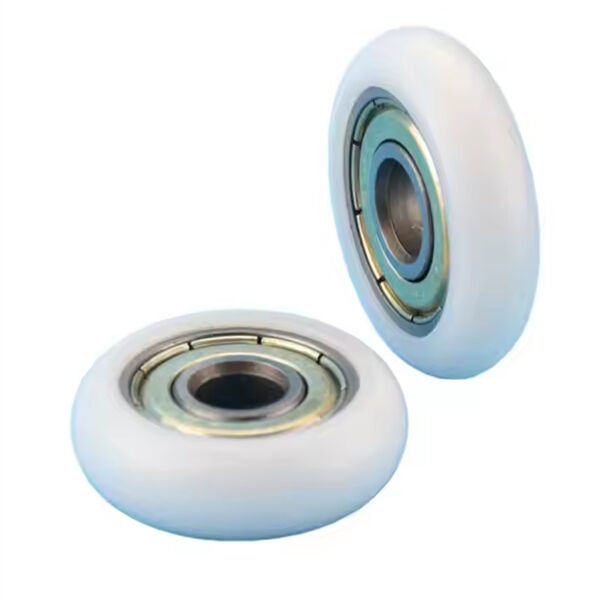

Rubber bearings are small components used for damping shake or vibration in machinery. They are therefore rubber, a soft and flexible material. Rubber bearings help support and prevent the machine shake too much during operation. This helps reduce machine movement as the soft rubber is able to absorb some of this movement.heroku This is advised because excessive shaking can damage the machine as well as the work being done by it.

This is why we use bearing sleeve typess on machines as well to make their movement smoother and seamless. A smoothly running machine is a time saver and energy saver which is extremely essential in a bustling work atmosphere. If machines perform better, they can accomplish tasks more quickly and it enables everyone to work in an efficient manner. Likewise, rubber bearings are also quite reliable and long-lasting. That means you wouldn't have to change them frequently, which can add up to a significant amount over the years!

Bulldozers, cranes and other heavy machines rumble and shake. Large pieces of machinery could be in use, but once that ground polish happens they are going to shake and rattle; this shaking will make it harder for the men to focus and get their jobs done safely. Rubber bearings are ideal in controlling this shaking by keeping the vibrations at bay. It allows the machine, which can tend to bounce around a bit, to really do its thing and safely work with larger swathes. Similarly, it can reduce any damage to the machine itself, which is vital for keeping everything operational.

These rubber bearings are so sturdy, which is used to eliminate structures dampers in high-tension environment. They are weather resistant for sunlight, heat, and water. That makes them well-suited to extreme places such as mines and factories, which frequently put machines under difficult circumstances. These rubber bearings are not only able to resist chemicals and oils in areas where this is possible. The durability of rubber in harsh environmental conditions contributes to long-lasting machines through the use of bearings.

Choosing the correct type of rubber bearing is essential for ensuring proper machine operation. Rubber bearings needed for different kinds of machines. Certain provide machines require a tender rubber and others, a tough rubber. Choosing the right rubber bearing depends on the dimensions and weight of the machine as well as the amount of vibration when in operation. In this manner, you can ensure the rubber bearing functions properly and efficiently.

CIXIHOTO has dozens of rubber bearings for all types of machines. The rubber bearings used in our products are durable and can effectively minimize wobbling or even earthing, which later helps improve the overall machine working as well. Our specialists are available to assist you in your selection of the correct rubber bearing type. Depending on what type of machine you have, they might offer advice on what it would need in order to run properly. Therefore, if you are looking for Rubber bearings support — contact us!

CIXI HOTO produce kinds of ball bearings, bearing component (rubber bearing and sleeves, balls, seal) and steel pipe bearings and we also provide single-stop service for ball bearings as well as a solution.

CIXI HOTO is a strong quality rubber bearing to ensure quality control. It is ISO9001-2016 certified. ISO14001: 2016. OHSAS18001.

CIXI HOTO offers thousands of bearing rubber bearing made of SS, Alloy, Carbon steel and bearing steel grades.

rubber bearing completed 40 production lines, allowing for the production of a rapid lead time.