Close your eyes for a moment and travel many, many years back into history when our ancestors were able to move heavy objects with nothing but brute force. That must be very difficult and exhausting! May be if we had some extension that signify us the same thing through which helped us to carry on the motion uninterruptedly, and here we have a little magic tool in mechanical way is known as linear sleeve bearing. We are Happy at CIXIHOTO Helping you out with these linear motion bearings to ease and comfort your life!!!

A linear motion bearing is a specialized equipment that eases the movement of objects along a straight-line path. Think about how smoothly a toy car slides across a surface; it is easy! Just like a linear motion bearing does. This reduces the attraction of the objects and causes the objects to run smoothly without getting stuck. These brilliant bearings you will discover in various machines and devices! They are used for robots to move parts around, conveyor belts that transport items, and even amusement park attractions like roller coasters! This allows these machines to complete tasks at a rate and duration greater than that of a human while needing no rest.

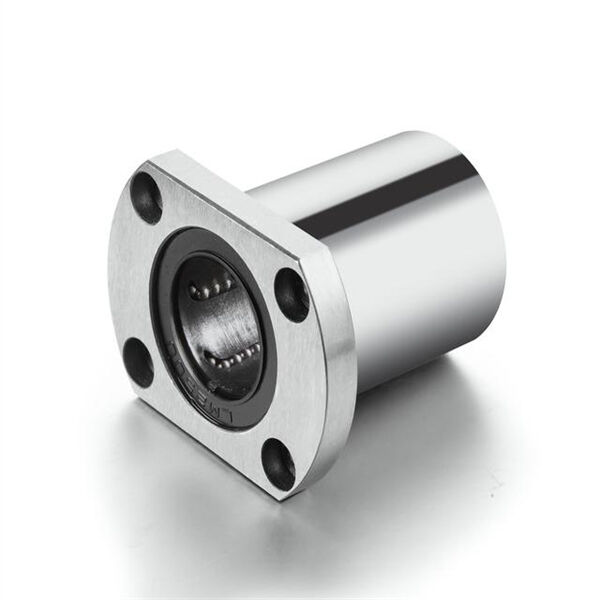

So you may ask how does a bearing sleeve function. Within a linear motion bearing, there are small spheres that run in circles. These tiny balls are incredibly important to keep things working properly. When something has to move, it rides upon its own special type of track, with the linear motion bearing lying beneath it. The bearing has a small ball inside that rolls along the track to allow easy gliding of the object. In other words, it will take less force to move it so the entire process is simplified and more efficient.

The advantages of linear motion bearings enable machines to operate at much higher speeds and last much longer. This is crucial for the machines performing their tasks more efficiently. The bearings will help to reduce friction (A force that resist the motion between two surface that are in contact). These bearings help the machine avoid friction and cause wear and tear. That means the machines can operate effectively for long periods of time between breakdowns or complications. Think about riding a bike with airless tires – tough, huh? You can ride steadily and go fast, but you must have proper tires. This is how linear motion bearings assist machines!

But this leads us to the next logical question; how are linear motion bearings made? These bearings are manufactured in some special technology and such methods. Then CIXIHOTO manufacturing, our bearings made of tough materials. We incorporate advanced manufacturing techniques to ensure that they are rugged and can withstand the rigors of daily use. This allows you to be confident that even when put through heavy use, our bearings will be solid and long-lasting.

Now, linear motion bearings come with a great load of advantages. To begin with, they aid in the lowering of friction, resulting in smooth and fast movement. This can be very helpful in machines because it makes them work better. Third, they may also help in prolonging the service life of several machines and equipment. By making use of the high-quality bearings, you can ensure that your machines will run better and for longer time durations. Not only does this do more for the environment, but it can also save you some money too since you will likely need to replace your equipment less often. Just imagine, if your bike is quite all right, you do not need to order a new bike too soon!