Bearings are a type of part that are used within larger machines. They assist these machines in functioning better by minimizing friction. Friction is prevention when two surfaces come into contact while rub against each other, this slows you down. Bearings ensure that the machine operates without jamming or mal-functioning. Bearings are very common in a lot of daily use devices such as vehicles that take you places and the kitchen appliances where we cook. This article will examine bearings more closely. We are going to know, what the bearings are, how they work and why these machine parts have essential importance.

Bearings are available in various shapes, sizes, and materials. As a result of this variety, every bearing type is unique and equipped to perform specific work. However, bearings can be clustered in a few different ways. One way to differentiate such types is based on how much weight they can bear, or we can classify them according to their made. Examples of the type of bearings are ball bearing, roller bearings or needle bearings.

Bearings have many important functions in machines. Their primary purpose is to help eliminate friction between two moving parts. So we just need to make sure not use too much friction, because if we do then pieces will wear out to quickly and have replace often. One more task of the bearings is to bear heavy loads. Machine as Engineering Science for hard work which can make sure machines lifts, move heavy with no breakdown.

The biggest benefit that bearings provide is the reduction of friction to allow machines to operate efficiently. An efficient bearing can ensure that the machines continue to run for prolonged intervals, by minimizing wear and tear on its moving components. It means that machines require fewer repairs, resulting in more time and cost savings. Additionally, bearings are typically inexpensive so their use helps minimize overall cost.

Bearings are of utmost importance component in heavy-duty machinery such as construction equipment, and mining machines. In an excavator, the bearings are applied to joint moving parts such as swivel circle and arm. These keep these pieces moving smoothly and efficiently as a well oiled machine. Without the bearings, an excavator simply would not be able to function and, in fact, it might breakdown more often.

Bearings are often described as the unsung hero of machines. This may sound trivial but in reality, these things might seem small and ignored but are crucial for machine performance. As you can tell from this problem, machines would have a much more difficult time operating properly without bearings, resulting in larger issues such as excess wear on components and poor efficiency. Due to their ability to carry out their responsibilities efficiently and certainly, the bearings serve as some of the essential parts of industry machines. They help these machines perform better every day.

Nowadays there are new, state of the art bearings assisting fast spinning machinery. For instance, magnetic bearings. The Magnetic Bearings — bearings that suspend the spinning components of a machine using magnets, rather than having to stand in contact with each other. That means, lower friction and thereby lesser wear, consequently improving machine performance. Hence magnetics bearings are favourable in high speed rotating machines like turbines and compressors. Regular bearings may not suffice because they might overheat due to the intense service condition and require constant lubrication.

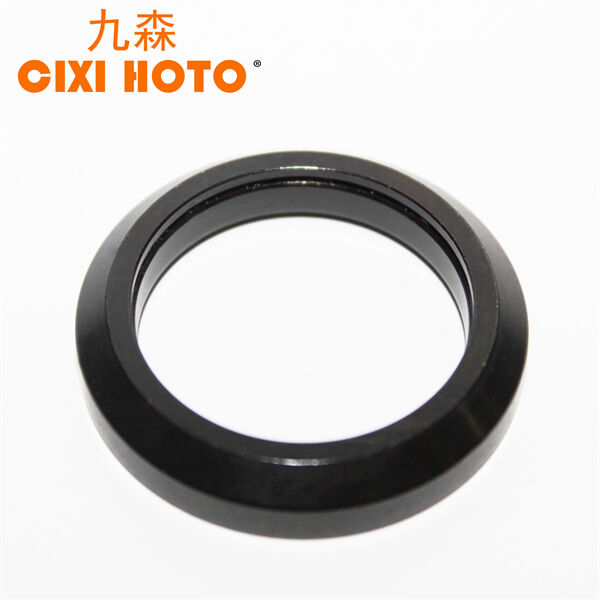

different types of bearings HOTO produce kinds of ball bearings, bearing component(cage sleeves, balls, sleeves, seal) and bearing steel pipe and we also provide one-stop ball bearing services and solution.

CIXI HOTO offers thousands of bearing sleeves that are available in SS and Alloy grades, as well as Carbon steel, as well as different types of bearings.

CIXI HOTO has completed 40 production lines. It also helped to achieve very different types of bearings lead times.

CIXI HOTO is a strong different types of bearings control system. It is ISO9001 certified. ISO14001: 2016. OHSAS18001.