Bearings and drives are crucial components on most of the machines that we use in daily life. They assist the machines functioning properly which makes them better performers. Bearings are tiny, round pieces that go between the machine and each of its moving parts. They are in place to enable those parts to move on smoothly without getting stuck. Drives, however, are what changes the direction of machines, or moves things around. They allow machines to perform a wide variety of functions. Bearings and drives make it possible for machines to perform their expected tasks in conjunction with each other.

Bearings are an essential part of various machines as they provide low friction and flexible movement. They help to eliminate what is known as friction. Friction is when two things rub together, and friction tends to stop things. An overabundance of friction in a shop is bound to heat things up, creating breakdowns that make the machine pay for its sins. This would definitely be harmful because it can create issues which will lead to the machine shutdown. Bearings reduce this by adding a nice smooth non-abrasive surface between the moving parts. This way the components are allowed to slide against eachother without getting blocked.

Drives are just as important. Some of them assist machines to rotate or rotate other objects. Some drives work like gears. Gears: These are round objects that can rotate and serve as mast parts to other moving components. For instance, if one gear rotates, it can move yet another gear without direct contact. Other drives can slide things up and down or back and forth. This is superimportant for all the different tasks that machines have todo. Drives enable a variety of machines to perform specific tasks, such as grinding flour into powder or assisting large vessels in traveling through water.

Different kinds of bearing sleeve exist. Bearings are typically made of metal or plastic, although some are rubber. One is used for a specific reason and the other on certain occasions. Different types of drives can be driven by power. Electricity powers some drives, while steam or even water may power others. So given that every machine requires unique bearings & drives to operate correctly. This is why each machine needs to be fitted out with the correct ones.

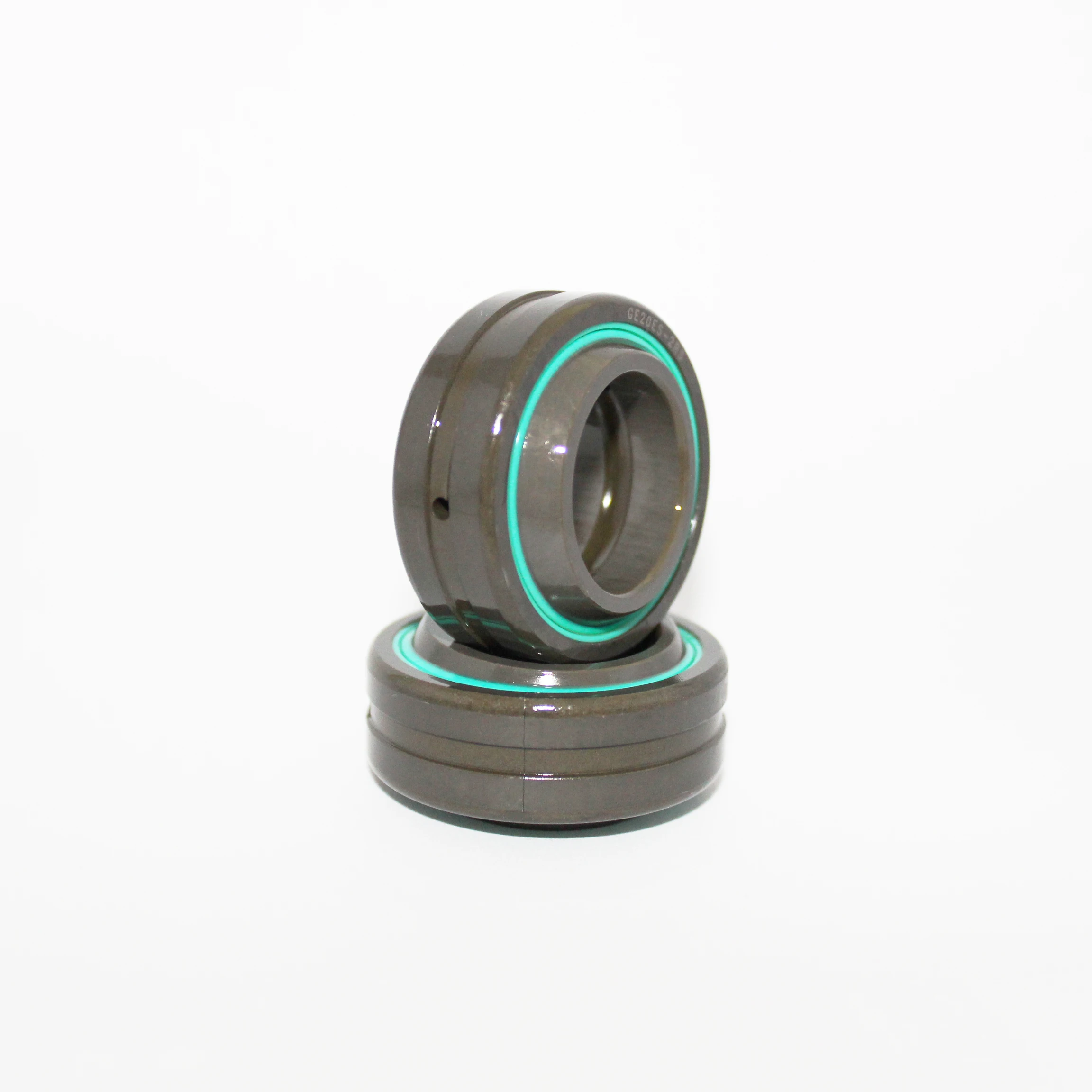

Being aware of common types of bearings can be very useful. The most popular types of bearings are ball, roller and needle. Ball bearings are rounded and come in small sizes. They help reduce friction by rolling between two surfaces. It allows machines to operate more smoothly. Compared to ball bearings, roller bearings are longer and can carry larger loads. They are very powerful to assist on larger machines. Needle bearings are slender and thin. This makes them ideal for high-speed, hi-fidelity moves and extremely useful in a wide variety of applications.

Drive TypesNeumark | VRCoach & Company The blog for all things Virtual Reality. September 25, 2022 | 5 min read Whenever we hear the word drive сейчас, it gets associated with futuristic cars or other products powered on electricity from a network of wires somewhere deep in the earth and is probably designed to orbit around the sun — but as enlightened souls as represented by us humans that have been blessed somehow in this point of time, we must now familiarize ourselves with what drives our robots! Storage Though storage drives come in various shapes and sizes such as HDD and SSD, there are two main types: AndrewSpoon58 Drive Type History More from The blog for all things Virtual reality You might also like How To Get A German Work Permit – Your Complete Guide Of 2023The Germans Have Us All Talking About Efficiency And Life-Work Balance As Workers At The Tail End Of Luggageсолютный учебникКак получить разрешение на работу в ГерманииРежимы выживанияДулевскиекоровицыząść nasZgadzaj się?

Machines also have drives that matter indeed. So here are the drives, you should know about. For instance, the belt drives make use of a flexible belt to rotate one part while another component remains static. This is a world normal within cars and some forms of machinery. A chain drive uses a chain in place of a belt to link together multiple rotating shafts. This one in particular is very hard wearing and excellent for heavy duty. When it comes to compound parts, gear drives employ a solution where one part turn to rotate while the other keeps idle — resulting in very efficient motion transfer via gears. Hydraulic drives that utilize liquid to help in the vertical aperture of things. There are lots of other varieties of drives and the suitable kind is determined by what sort of machine you're using.

CIXI bearings and drives completed 40 production lines, which allowed for the production of a rapid lead time.

bearings and drives HOTO is a strong quality control system for quality control. It is ISO9001-2016 certified. ISO14001: 2016. OHSAS18001.

CIXI HOTO offers thousands of bearing sleeves made of SS, bearings and drives, Carbon steel, and other bearing steel grades.

CIXI HOTO produce kinds of ball bearing and bearing component (cage, bearings and drives, balls, seal) and steel pipe bearings, we do supply the ball bearing service in one stop and a solution.