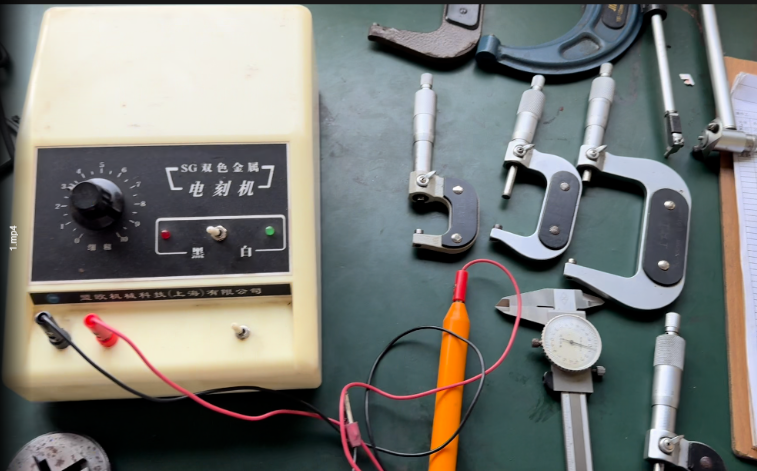

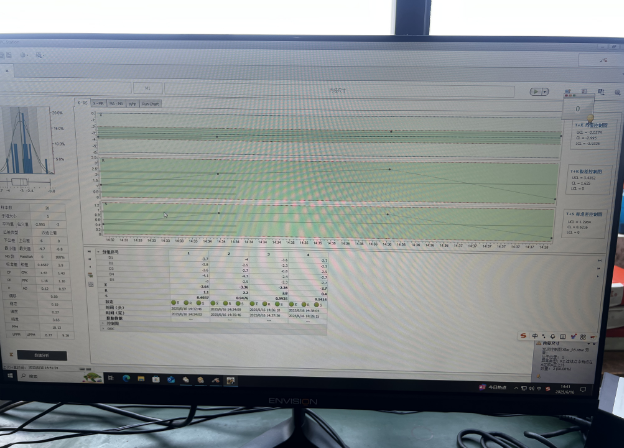

CPK is a statistical metric used to assess the stability of production processes and product quality. A higher CPK value indicates less dispersion in the production process, indicating greater stability and better product quality. CPK size inspection plays a crucial role in modern manufacturing, helping companies effectively control product quality and enhance production efficiency. By analyzing and applying CPK values, companies can continuously optimize their production processes, achieve continuous improvement, and ultimately meet higher quality standards. CIXI HOTO uses CPK devices and other data to monitor our product production in real time, ensuring the quality of our custom-made kinds of bushings. Our custom-made bushings are primarily used in textile bearing inner and outer rings , automotive bearing components, truck trailers, and other mechanical parts. We welcome inquiries and purchases!